Normal operating exhaust capacity

One of the most significant technical changes to the new codes is the change in determining exhaust rates from using room counts to using bedroom counts. This decrease in capacity at first glance seems counterintuitive and at odds with industry standards such as CAN/CSA-F326-M, “Residential Mechanical Ventilation Systems.” The F326 standard still applies when the bedroom count is over five, and is still referenced in most manufacturers’ start-up procedures for ventilation equipment such as Heat Recovery Ventilators. For those inspectors who love interpreting code and reading the reasons behind code provisions, the new intent statements are a valuable resource when explaining code infractions to contractors. The explanatory material in the appendix is often dry, however, the explanation of bedroom counts in determining exhaust rates was informative and a good read. The following was extracted from the 2010 NBCC:

A-9.32.3. Heating-Season Mechanical Ventilation. For many years, houses were constructed without mechanical ventilation systems. They relied on natural air leakage through the building envelope for winter ventilation. However, houses have become progressively more airtight through the introduction of new products and practices, e.g. the substitution of panel sheathings, such as plywood and waferboard, for board sheathing, the replacement of paper-backed insulation batts with friction-fit batts and polyethylene film, improved caulking materials, and tighter windows and doors.

Following the energy crisis in the early 1970s, considerable emphasis was placed on reducing air leakage in order to conserve energy. Electric heating systems were encouraged and higher-efficiency furnaces were developed, which further reduced airchange rates in buildings. This led to concern that the natural air change in dwelling units might be insufficient in some instances to provide adequate indoor air quality. Condensation problems resulting from higher humidity levels were also a concern. Evolution of NBC Ventilation Requirements Mechanical ventilation requirements in the NBC have evolved from a simple requirement in the 1980 edition that exhaust fans be incorporated in electrically heated houses, through requirements in the 1985 and 1990 editions that all houses have mechanical ventilation systems capable of exchanging the indoor air for outdoor air at a specified rate: 0.5 air changes per hour in the 1985 edition and 0.3 air changes per hour in the 1990 edition.

The 1995 NBC addressed not only the overall air change rate created by the mechanical ventilation system but also the need to ensure that the outdoor air brought into the house by the system is distributed throughout the house.

Current Requirements

The current requirements are a further refinement. The ventilation systems described herein are essentially the same as those described in the 1995 NBC but additional provisions have been included with the following goals in mind:

provisions that are easier to understand,

reduced probability that outdoor air distributed through a forced-air heating system will be cool enough to cause premature deterioration of the furnace heat exchanger, and

reduced probability that the ventilation system will cause excessive depressurization of the dwelling unit.

To some extent, the first of these goals conflicts with the other two and its achievement has suffered accordingly. Only in the manner of determining the capacity of the principal ventilation fan [see Sentence 9.32.3.3.(2)] has any significant simplification been achieved. See also Appendix Note A-9.32.3.3.(2).

9.32.3.3. Principal Ventilation System

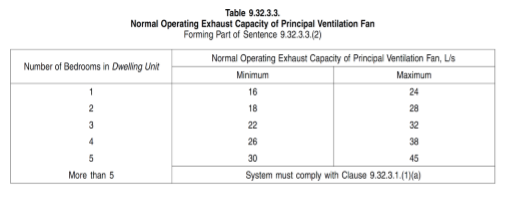

2) The principal ventilation fan shall be capable of operating at an exhaust capacity complying with Table 9.32.3.3., referred to hereinafter as the “normal operating exhaust capacity.” (See Appendix A.)

A-9.32.3.3.(2) Normal Operating Exhaust Capacity. The principal ventilation fan operates at a rate known as the “normal operating exhaust capacity.” This rate is intended to be suitable for use on a continuous basis at any time that an ongoing, background level of ventilation is needed, e.g. the late fall or early spring when air leakage driven by wind and inside/outside temperature differences is lowest but it is too cold to rely on open windows.

The capacity of the principal ventilation fan is determined on the basis of the number of bedrooms in the house rather than on the basis of some fraction of the house volume, as in previous editions of the NBC. This is because the amount of ventilation required is

related to the activities of people, and the number of people in the house is usually related to the number of bedrooms rather than to the size of the house. It should be emphasized that this air change rate refers to the installed capacity of the system, not to the rate of ventilation that is actually used in the house.

In many households, ventilating even at the background rate would provide more ventilation than required, resulting in unnecessarily high heating bills and perhaps excessively low indoor relative humidity. Thus, although a system with the minimum capacity must be installed, it can incorporate controls that allow the system to be used at less than its full capacity most of the time.

A maximum is set for the capacity of the principal ventilation fan because, if it were to be much larger than the ventilation needs of the household, it might never be used. The principal ventilation fan is intended to provide a relatively low level of ventilation such that it can be run continuously without too much noise and without serious energy penalty. If the installed capacity exceeds the minimum by a large margin and the fan flow cannot be reduced, there is increased probability that the fan will not be used at all, thus defeating the purpose of having it in the first place. Sentence 9.32.3.3.(2) therefore places limits on oversizing.

Part of the Eagle's Eye on Housing series - read more